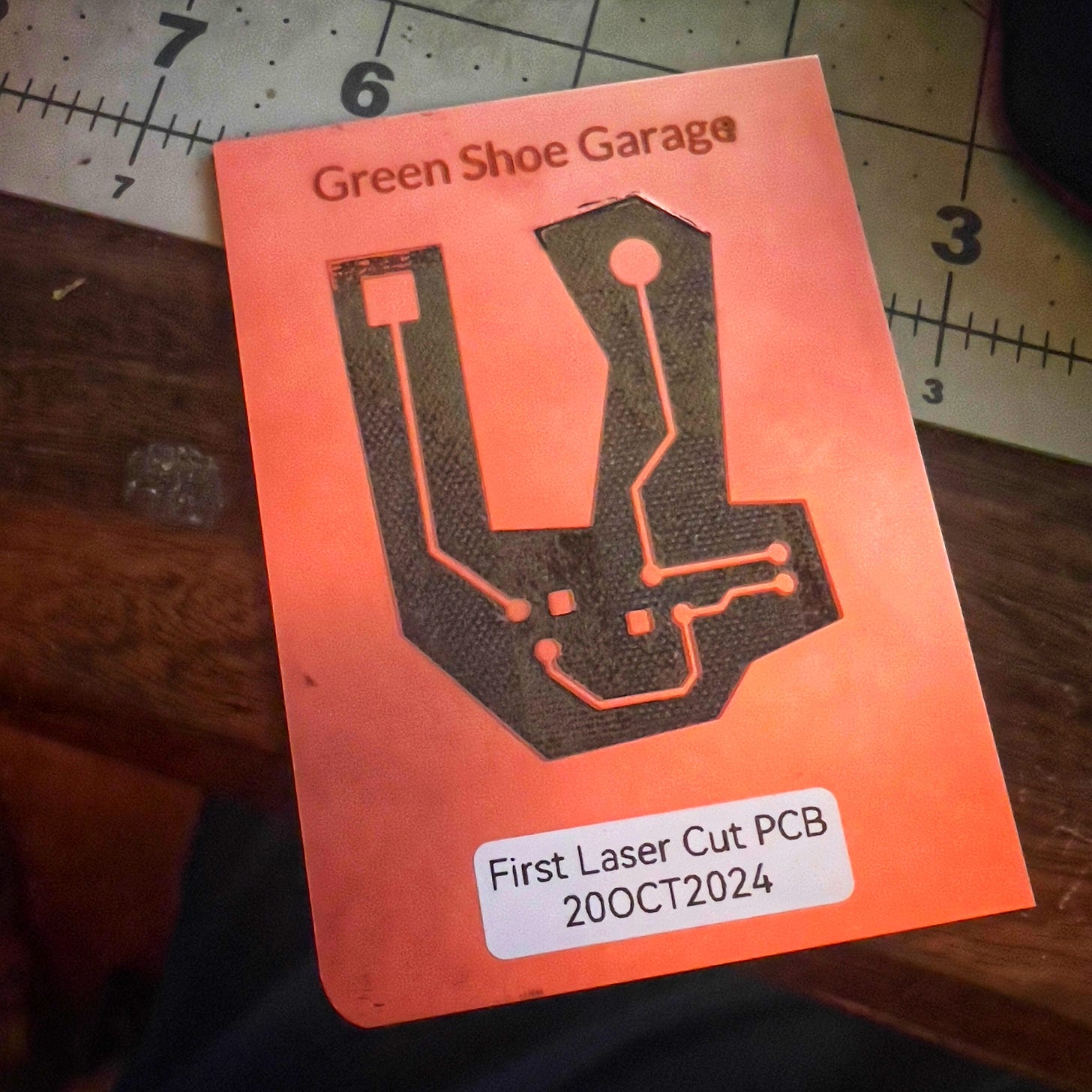

At 20W, the XTool F1 Ultra is not the most powerful fiber laser on the market, but the operating experience is amazing. And believe it or not, 20W is enough to make a circuit board with copper-clad FR4 fiberglass boards. It just takes some patience.

The following is based on my experiments. I am not claiming it is the best process, but it seems to work for the copper-clad board I have on hand. In general, there are two setting groups that we need to alternate between an ENGRAVE pass and a CLEANUP PASS. I recommend starting with the settings listed below and tweaking power and frequency until you get something that works for you. Vary the speed only as a last resort. The settings are as follows:

ENGRAVE PASS 10X

Power 100

Speed 1400

Pass 10

LPC 300

Mode Bidirectional

Freq 32 kHz

ENGRAVE PASS 1X

Same as the ENGRAVE 10X pass but now we only make 1 pass. This is reserved to when we are getting close to the end of the process.

Power 100

Speed 1400

Pass 1

LPC 300

Mode Bidirectional

Freq 32 kHz

CLEANUP

Power 85

Speed 1400

Pass 1

LPC 300

Mode Bidirectional

Freq 45 kHz

THE PROCESS

Run ENGRAVE 10x profile over and over until brown surface begins to show (1 - 3 repeats)

Run the CLEANUP once. Notice that if there is still copper, the laser sparks will burn BLUE at that spot. Once you hit the fiberglass, it will be ORANGE. At the end of the CLEANUP pass, the areas with copper will be shiny again.

Repeat the ENGRAVE 10x, followed by CLEANUP, until a very small amount of unwanted copper remains. You can verify this with a multimeter using continuity mode.

Once only a small amount of copper remains to be removed, alternate between ENGRAVE 1X and CLEANUP until the laser sparks are only ORANGE and the part of the board that we are etching away is no longer shiny. Clean up with rubbing alcohol and run a continuity test with a multimeter.

Once the negative space is brown, and the continuity test shows no shorts, one final clean with rubbing alcohol, and you are DONE!

NEXT STEPS:

Cutting holes for through-hole components.

Apply a solder mask, cure it, and etch away at the pads.

Cut out the circuit board from the blank.